Rewards

.

CANADA

55 Village Center Place, Suite 307 Bldg 4287,

Mississauga ON L4Z 1V9, Canada

Certified Members:

.

Home » IoT Solutions for Real-Time Logistics Monitoring

The Internet of Things (IoT) is transforming logistics by connecting physical objects and sensors to the internet, enabling real-time data collection and exchange. The IoT facilitates improved supply chain management by providing instant updates on the location and condition of goods in transit. It highlights the various benefits of IoT in logistics , such as real-time tracking, predictive maintenance, route optimization, enhanced safety, and efficiency improvements.

In this blog we will explore these advancements, emphasizing how data-driven decision-making and advanced monitoring contribute to businesses’ competitiveness and address contemporary challenges in logistics.

Traditional logistics often grapple with inadequate real-time visibility into inventory levels, shipment statuses, and fleet operations, leading to delays, inefficiencies, and missed opportunities. According to Gartner, a significant 70% of companies still rely on manual processes for tracking inventory and shipments, highlighting the pervasive issue of limited visibility in the industry.

Manual tracking and data entry remain prevalent in traditional logistics operations, posing challenges such as time-consuming procedures and error-prone outcomes. The Council of Supply Chain Management Professionals (CSCMP) estimates that errors from manual data entry contribute to between 10% and 15% of overall supply chain costs, underscoring the financial impact of outdated methods.

In today’s digital era, customers and stakeholders increasingly demand transparency and real-time updates from logistics providers. They expect precise information about shipment statuses, delivery timelines, and inventory availability. A survey by Deloitte reveals that a substantial 83% of consumers prioritize real-time visibility into their orders. Furthermore, 78% consider accurate tracking a critical factor influencing their purchasing decisions, highlighting the growing importance of visibility and transparency in logistics operations.

Get free Consultation and let us know your project idea to turn into an amazing digital product.

GPS-enabled devices are integral to modern logistics, providing real-time location data for vehicles, containers, and shipments by utilizing satellite signals to pinpoint precise geographical coordinates. Logistics companies leverage GPS tracking to optimize routes, monitor delivery progress, and enhance overall fleet management, ensuring IoT real-time monitoring. This technology enhances delivery accuracy, reduces transit times, and enables better resource allocation. For instance, a delivery truck equipped with a GPS tracker allows logistics teams to track its movement, estimate arrival times, and promptly reroute if necessary.

IoT sensors designed for monitoring environmental conditions within containers and storage areas are crucial for maintaining the quality and safety of goods. These sensors are particularly vital for perishable items like food, pharmaceuticals, or flowers, as well as sensitive materials such as electronics. By continuously monitoring temperature and humidity levels, logistics teams can prevent spoilage, ensure compliance with safety standards, and maintain product quality. For example, a temperature sensor installed in a refrigerated container can alert logistics personnel if temperatures exceed safe limits, allowing for immediate corrective action.

Logistics are changing the way they handle inventory and tracking procedures, and RFID (Radio Frequency Identification) tags and barcode scanners are essential to this change. Compact electronic devices with unique identifiers, or RFID tags, can be read wirelessly, while barcodes, which are printed labels with machine-readable information, allow for quick data collection. These solutions speed up warehouse operations and guarantee accurate inventory counts, which improves operational efficiency. For instance, quickly updating inventory data by the reading of an RFID tag on a pallet streamlines logistical processes and reduces human error.

IoT-enabled cameras play a pivotal role in logistics, enhancing security and operational efficiency within facilities. These cameras provide logistics real-time surveillance, detecting intrusions, theft, or unauthorized access. They also monitor operations during loading/unloading to ensure compliance with safety protocols and optimize traffic flow to improve layout efficiency. The benefits of video surveillance in logistics include heightened security, enhanced process visibility, and increased operational efficiency. For example, cameras strategically placed throughout a distribution center can deter theft, ensure adherence to safety protocols, and optimize operational workflows by providing real-time insights into facility activities.

IoT-based fleet management systems are designed to optimize the efficiency and performance of vehicle fleets in logistics operations. These systems incorporate various components, including real-time vehicle diagnostics for monitoring engine health, fuel efficiency, and maintenance needs; route optimization algorithms that consider factors such as traffic conditions, weather forecasts, and delivery schedules to identify the most efficient routes; and driver behavior monitoring to track performance metrics like speed, braking behavior, and idling times to enhance safety and operational efficiency.

The benefits of implementing fleet management systems include reduced fuel costs, minimized downtime through proactive maintenance scheduling, and improved overall fleet safety. For instance, a fleet management system can alert logistics personnel when a vehicle requires immediate maintenance or if a driver deviates from the planned route, enabling swift corrective actions to be taken.

Feasibility Assessment

The initial phase of integrating Internet of things solutions for real-time logistics monitoring hinges on conducting a comprehensive feasibility assessment. This assessment critically evaluates the compatibility of IoT technologies with existing logistics systems and identifies operational pain points that stand to gain from real-time monitoring solutions. Thoroughly assessing costs and ensuring compatibility with infrastructure are essential steps to ensure strategic alignment with business objectives.

Pilot Testing

Following the feasibility assessment, pilot testing plays a pivotal role in validating the effectiveness of IoT devices in real-world logistics environments. These small-scale tests explore various scenarios, such as logistics live monitoring through live tracking of shipments, environmental monitoring of storage conditions, and real-time asset management. Data collected from pilot tests provides insights into performance and reliability, guiding informed decision-making for broader deployment.

Integration Steps

Carefully planning integration steps is essential to ensure smooth communication and data exchange within the logistics ecosystem. Gradually integrating IoT devices guarantees consistent and reliable real-time data transmission. Building strong communication channels between sensors, gateways, and backend systems facilitates prompt updates and notifications. Prioritizing interoperability and scalability allows for agile responses to evolving logistical demands.

Data Management

IoT devices generate vast amounts of data, necessitating efficient collection and storage mechanisms. Real-time data collection using cloud platforms or edge computing ensures swift and accurate insights. Choosing appropriate storage solutions, such as scalable databases or data lakes, enhances accessibility while prioritizing data security and compliance.

Training and Adoption

Comprehensive training and adoption initiatives are essential to maximize the benefits of IoT technologies across logistics operations. Educating logistics personnel on IoT device functionalities and their role in real-time monitoring is crucial. Training encompasses device operation, troubleshooting procedures, and interpretation of real-time data analytics. Engaging stakeholders, including management, drivers, and warehouse staff, fosters a collaborative approach towards embracing IoT services. Proactively addressing change management challenges highlights efficiency gains and enhances decision-making capabilities enabled by real-time IoT solutions.

Inventory Tracking and Optimization

IoT sensors placed on shelves and pallets provide real-time tracking of inventory levels. Warehouse managers receive alerts for low stock or items needing replenishment. For example, a retail warehouse uses RFID tags to monitor clothing inventory, ensuring timely restocking.

Automated Material Handling

IoT-enabled robots and conveyors automate material movement within warehouses, optimizing processes like picking, packing, and sorting. Amazon’s Kiva robots, for instance, transport shelves to human workers for efficient order fulfillment.

Real-time vehicle tracking

GPS-enabled devices track trucks, delivery vans, and ships, allowing logistics companies to monitor routes, estimated arrival times, and deviations. For example, a courier company uses GPS trackers to provide accurate delivery updates to customers.

Predictive Maintenance

IoT sensors collect vehicle performance data such as engine health and tire pressure. Predictive algorithms use this data to schedule maintenance before breakdowns occur. For instance, a trucking fleet schedules maintenance based on sensor data to reduce downtime.

Fuel Optimization

IoT analytics optimize fuel consumption by analyzing driving behavior and routes, helping companies reduce fuel costs and environmental impact. For example, a logistics provider uses route optimization software to minimize fuel usage.

Temperature-Sensitive Shipments

IoT sensors monitor temperature and humidity of perishable goods during transport, triggering alerts if conditions deviate from safe ranges. For example, pharmaceutical companies use IoT to ensure vaccines are stored at the correct temperature.

Compliance Assurance

IoT data provides an audit trail for regulatory compliance, such as FDA or USDA requirements. Records demonstrate adherence to temperature and safety regulations. Food distributors, for instance, use IoT logs to prove compliance with food safety regulations.

Real-Time Video Monitoring

IoT cameras monitor warehouses, loading docks, and parking lots, providing real-time video monitoring to alert security personnel to suspicious activity. For example, a logistics hub uses logistics real-time video monitoring to prevent theft and unauthorized access, ensuring enhanced security and operational efficiency.

Access Control

IoT-enabled access cards or biometric systems manage entry points, restricting access to authorized personnel only. A distribution center, for instance, limits access to sensitive inventory zones.

Intrusion Detection Systems

IoT sensors detect unauthorized entry through doors, fences, or windows, triggering alarms to notify security teams instantly. Motion sensors at logistics yards, for example, help prevent cargo theft.

These IoT solutions in logistics enhance operational efficiency, ensure regulatory compliance, and strengthen security measures, making them indispensable tools for modern supply chain management.

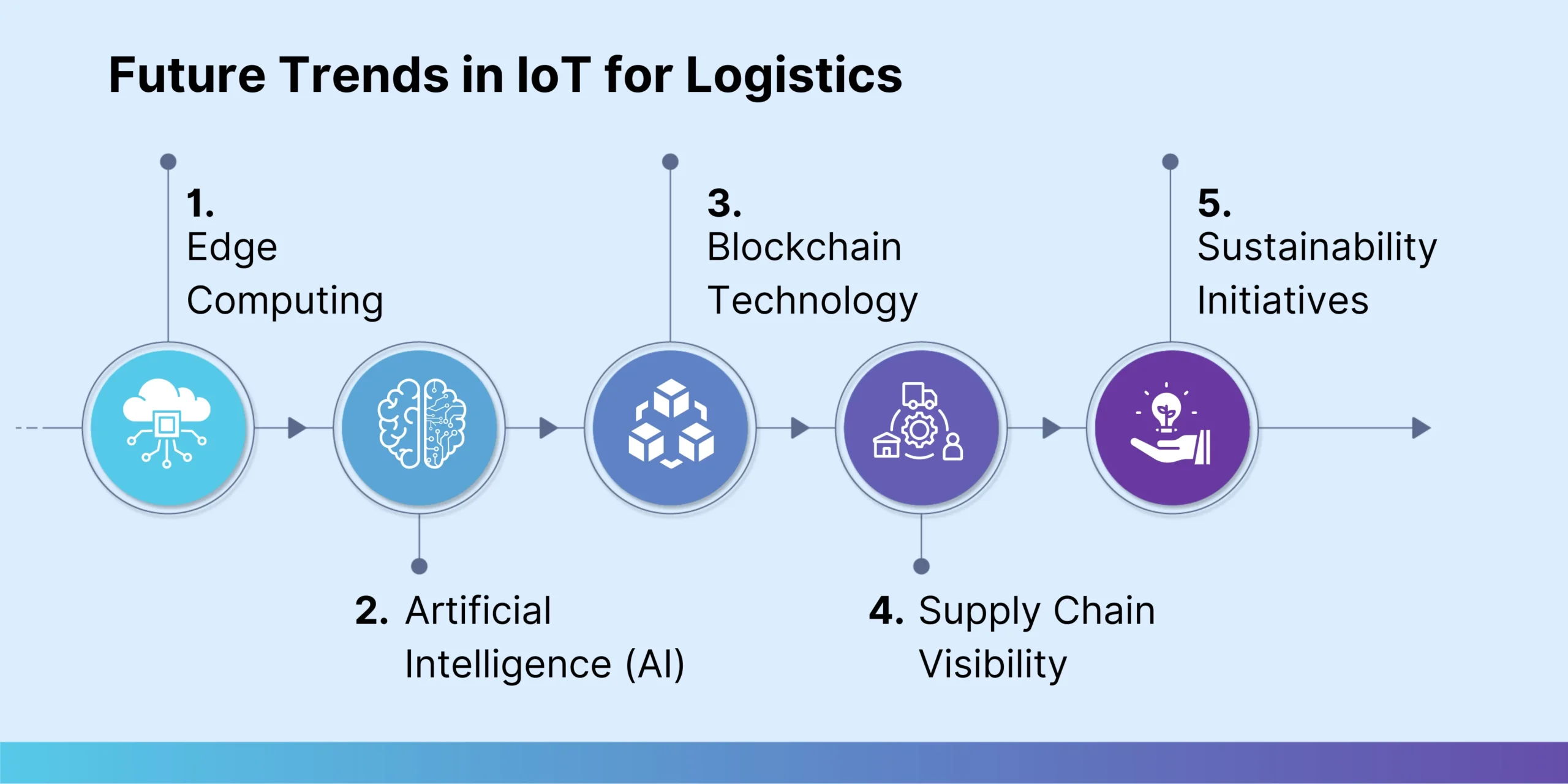

Edge computing processes data at or near its source, such as sensors, to accelerate decision-making, reduce latency, and enhance system reliability. By 2025, an estimated 75% of enterprise-generated data is projected to be processed at the edge, highlighting its critical role in improving operational efficiency in logistics.

AI algorithms use Internet of Things (IoT) data to optimize logistical procedures, enhancing the accuracy of demand forecasts, cost effectiveness, and resource allocation. The potential of AI to improve decision-making and streamline operations is predicted to propel the global market for AI in supply chains, which is projected to reach $10.1 billion by 2025.

Blockchain ensures secure transactions within supply chains, enhancing visibility, reducing fraud, and facilitating efficient cross-border operations. With a projected CAGR of 82.59% from 2020 to 2025, blockchain in logistics promises to revolutionize transaction management and stakeholder trust.

IoT enables real-time tracking of goods, providing insights into inventory levels, shipment statuses, and delivery timelines. Companies with end-to-end supply chain visibility achieve lower inventory levels and faster cash-to-cash cycles, optimizing supply chain operations.

IoT monitors environmental factors like emissions and energy usage, promoting eco-friendly logistics practices. This enables cost-effective route optimization and compliance with environmental regulations, contributing to reduced transportation costs and environmental impact.

This version presents each trend succinctly, focusing on key benefits and statistics to convey the transformative potential of IoT in the logistics industry.

IoT in logistics offers undeniable benefits, transforming supply chain operations with real-time tracking and monitoring. Embracing IoT solutions enables data-driven decisions, optimized operations, reduced costs, and enhanced customer experiences. As technology advances, IoT’s agility and efficiency position businesses to thrive in dynamic market conditions. The choice to harness IoT’s power and lead the industry into an innovative future lies in embracing transformative change in logistics operations.

For a deeper understanding of IoT’s impact, read our blog “Role of IoT in Enhancing Supply Chain Visibility and Efficiency.“

Our Articles are a precise collection of research and work done throughout our projects as well as our expert Foresight for the upcoming Changes in the IT Industry. We are a premier software and mobile application development firm, catering specifically to small and medium-sized businesses (SMBs). As a Microsoft Certified company, we offer a suite of services encompassing Software and Mobile Application Development, Microsoft Azure, Dynamics 365 CRM, and Microsoft PowerAutomate. Our team, comprising 90 skilled professionals, is dedicated to driving digital and app innovation, ensuring our clients receive top-tier, tailor-made solutions that align with their unique business needs.

AI is shaking up logistics and supply chain management like never before. A Marketsand Markets report predicts that the AI in supply chain market will soar from $730 million in 2020 to a whopping $10.1 billion by 2025, with a CAGR of 45.3%. This explosive growth shows just how powerful AI can be in making operations more efficient, cutting costs, and improving decision-making.

In today’s highly competitive e-commerce landscape, efficient inventory management is essential for success. For businesses distributing products from multiple warehouses, inventory management goes beyond cash flow

In the ever-evolving world of technology, one question persists: How are businesses staying ahead of the curve? McKinsey’s recent findings offer an intriguing insight: a significant one-third of organizations are now tapping into the potential of Generative AI (Gen AI) in their daily operations. This makes us ponder: What exactly is Gen AI,

IoT in logistics refers to the integration of physical devices (such as sensors, trackers, and connected devices) through the internet. These devices collect, exchange, and analyze data related to assets, vehicles, warehouses, and shipments. By leveraging IoT, logistics companies can achieve real-time tracking, optimize processes, and enhance efficiency.

Real-time tracking involves embedding IoT devices (such as sensors and GPS trackers) in shipments, vehicles, or containers. These devices continuously monitor and report data, allowing logistics managers to track the location, condition, and status of assets throughout the supply chain2.

IoT offers several advantages:

The IoT market in logistics is growing rapidly. It was estimated to be worth USD 37.41 billion in 2021, with projections reaching USD 93.85 billion by 2028. This signifies the increasing recognition and adoption of IoT technology within the logistics industry

Schedule a Customized Consultation. Shape Your Azure Roadmap with Expert Guidance and Strategies Tailored to Your Business Needs.

.

55 Village Center Place, Suite 307 Bldg 4287,

Mississauga ON L4Z 1V9, Canada

.

Founder and CEO

Chief Sales Officer

🎉 Thank you for your feedback! We appreciate it. 🙌